| During landing, as the static wheels to the runway surface, an extensive heat is generated and the melted rubber from the tires, is smeared on the runway. In time this thin layer of rubber thickens and fills the cavities of the “anti skid layer”. Consecutively, especially when wet, this thick layer of rubber deposit is suggested to be one of the major risk factors jeopardizing the landing safety. 1 Graham Bailey is a Canberrabased aerodrome consultant.

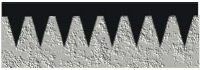

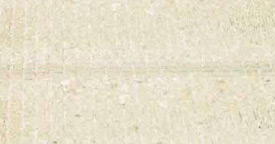

Pictures 1 and 2, demonstrate the layer of the rubber deposit both after a single landing and after three months’ time.

Picture 1

AHL (Istanbul International Airport)

Runway 06-24 |

Picture 2

AHL (Istanbul International Airport)

Runway 06-24 |

|

|

Above photos were taken from a runway that is closed everyday between 06 :00 and 24:00 for cleaning. However the cleaning of the said runway is made by the airport authorities using high pressure water jet. We shall go into the details of various cleaning methods in the coming chapters.

When the water jet is applied with 1700 – 2000 bar pressure, it cleans the rubber deposit completely; however, it also destroys the “anti skid” layer covering the surface of the runway. Consequently, although this process cleans the rubber deposit, by destroying the “anti skid” layer completely just after 2 cleanings, it causes more harm than good.

The anti skid layer costs approximately 20€ per sqm to renew. Moreover, the renovation of this layer requires a construction period, during which the runway will be closed to traffic.

For this reason, many runways are being cleaned by low pressure water jet on a level of 700 bars but yet, under this compression, it is not possible to clean the rubber deposit completely.

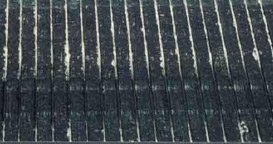

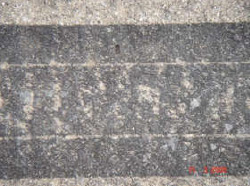

Pictures 3, 4 and 5 demonstrate the clean anti skid layer, a dirty one and one damaged by high pressure water jet.

Picture 3

A profile of a new runway surface |

Picture 4

A profile of a dirty

(tarnished) runway surface |

Picture 5

A profile of a destroyed runway surface |

|

|

|

Runways of the Istanbul International Airport, like many runways of East European airports have lost this "anti skid" layer completely because of the damage by water compressed cleaning vehicle and consequently all these runways have become flat and extremely slippery.

Below pictures represent as an example, of the ideal runway surface and the photos showing their state after being cleaned by the water jet help us realize how false cleaning application destroys the runways and creates a safety risk.

Picture 6 – 7 ( An ideal runway surface)

The anti skid layer hasn't been destroyed and it functionally holds.

| Clean runway surface |

A runway surface with rubber deposit |

|

|

| |

|

Picture 8

A profile of a runway surface with no anti skid layer

(Ist. Int. Airport. runway 06-24) |

Picture 9

A profile of a runway surface with no anti skid layer

(Ist. Int. Airport. runway 06-24) |

|

|

| |

|

Picture 10 -11

Runway surface completely covered with rubber deposit (Ist. Int. Airport. runway 06-24) |

|

|

Color Codes Used For the Headings of the Pictures 6-11:

| GREEN |

The runway surface which poses no treat to landing safety . |

| ORANGE |

Low risk runway surface still having " anti skid" function despite having been dirtied by rubber deposit. |

| PURPLE |

A runway surface which is open to risks such as rubber deposit, mass of water and freezing due to loss of anti skid function", |

| RED |

A runway surface with no "anti skid function" and below safety standards due to rubber deposit on it. |

Additionally, Pictures 12 and 13 reveals that, even under low compression, keeping the water jet vehicle at one point for five seconds has caused a deep cavity on the runway. (The area marked with yellow circle) This track is the proof showing how the compressed water system damages the runway surface.

Picture 12

Picture 13

At the airports where the international safety rules are strictly applied, complete cleaning periods are carried out once a year in order to prevent anti skid layer from being damaged. At the airports where the international safety rules are strictly applied, complete cleaning periods are carried out once a year in order to prevent anti skid layer from being damaged.

In spite of this, after two years' time which includes two cleaning up periods, it becomes necessary to renovate the layer .Thanks to chemical cleaning systems which don't damage the "anti skid" layer, the intervals of runway cleaning have been decreased to once in 3 or 6 months although it was required once in a year before.

Another disadvantage of the high pressure water jet application is to the runway grouting which cracks and becomes out of order in a very short period of time.

Space among the concrete tiles forming the runway are filled using elastic grouting which protects the runway surface against being damaged during a possible bending or expansion due to thermal changes. While the grouting functions as a protector, it isolates the space, in which it is applied, against water. The cracks and tears on the grouting cause this isolation to weaken, so water penetrates deep into the concrete and it decreases its resistance.

The chemical cleaning solutions don't entertain such risks. However, the use of chemicals before Air-O has not been very popular as they were not only difficult to apply and caused environmental pollution, but also it threatened the personnel's health.

The detailed information related to this matter is covered under the relevant heading. |